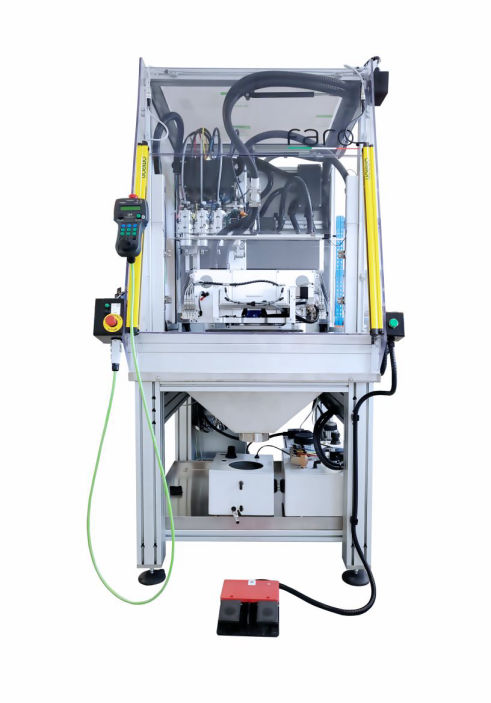

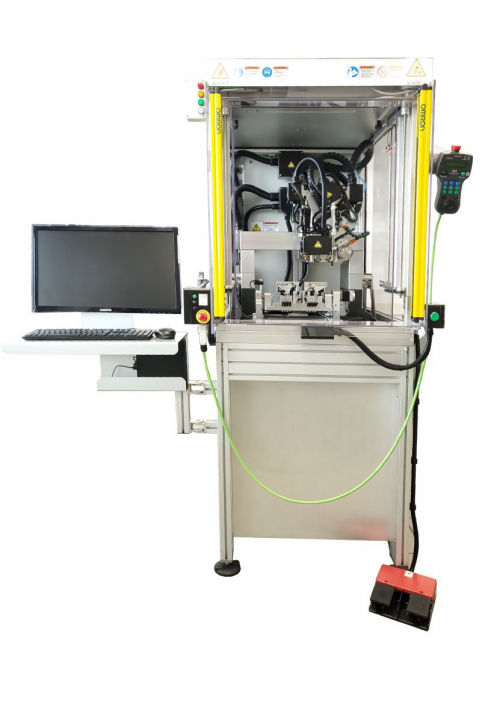

NEW!!! F7

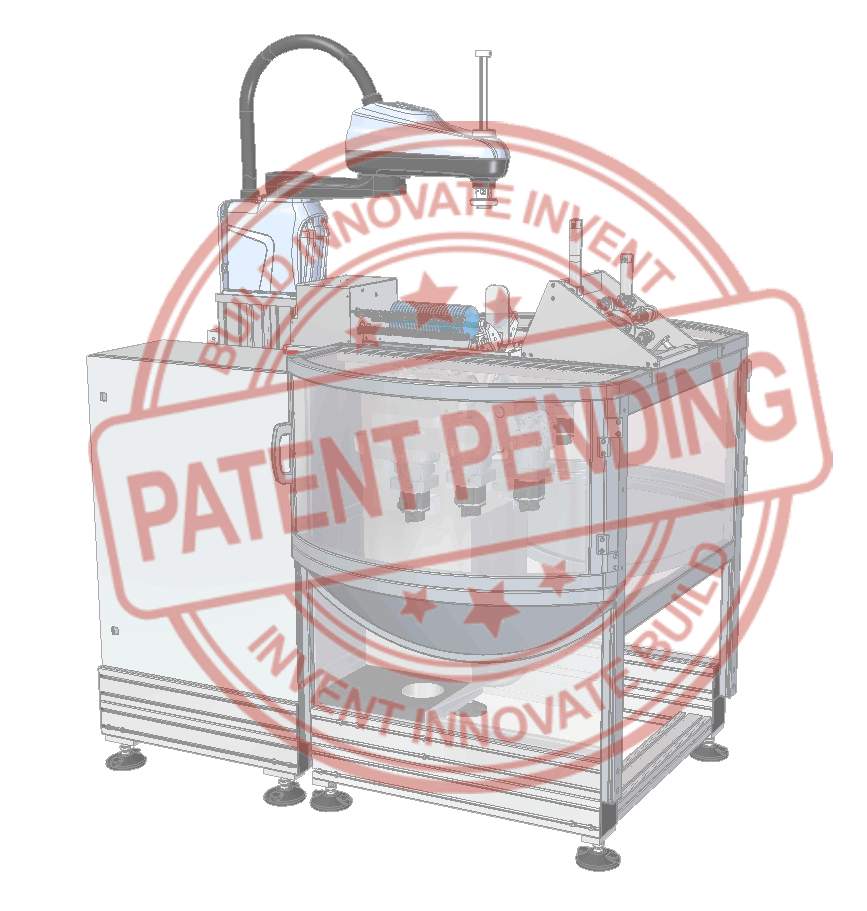

Faro F7 CNC completely redesigns the concept of the production of presentation and sunglasses lenses. Conceived to adapt to the needs of each company, thanks to its exclusive modular structure it can be configured in its BASIC version to perform lens shaping with a single tool and automatic loading (with unloading on belt), or with the following options:

Available Options

- Automatic Tool Change (Magazine with 6 positions)

- Drilling in masked time with 5 degrees of freedom.

- Automatic loading/unloading (from tray or thermoformed).

- Laser marking in masked time.